|

************

| |

Bags,

Accessories, Kits, Pumps & Glue Priced on this page...See

Below......

|

CLICK ON PICTURE TO SEE:

VACUUM FRAME

PRESSES |

| VACUUM

BAG KITS, ACCESSORIES AND

GLUE |

|

At last! Economical vacuum bag systems that can veneer, form

curved parts

or

clamp. Designed by professionals for easy use by anyone… professionals

or hobbyists, and it is affordable. Based on our popular building block system that allows

you to get started for a low minimum investment and to expand the systems capability

as needed. Our kits shown below have

everything you need to get started. Please read

through all of our info below, you will find our kits, bags,

glue recommendations, tips and more...

|

|

Here is how we make it easy for you…

|

|

|

|

GETTING

SET-UP

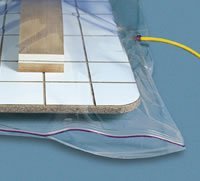

Getting the bag ready is easy! Our exclusive electronically

welded through-valve on all of our

bags eliminates your cutting

holes in the bag and installing difficult to seal valves.

First press the vacuum hose through the valve, tighten the clamp around the valve stem, and you’re ready.

|

|

|

|

|

|

OUR KITS: |

Please

E-MAIL US

if

you have questions about our Vacuum Bagging products.

____________________________________________________

MORE CHOICES,

MORE POWER!!!

The Pro

6

& 10

Mold

and vacuum board not included.

The

MARK 6 and MARK 10 are electronically regulated, completely self

contained, rotary vane vacuum pumps . They do not require an air

compressor to create a vacuum. These pumps have been especially

modified to match them perfectly with the vacuum bag veneering,

forming and clamping applications. The system is controlled by

an illuminated, three position switch giving the operator the

choice of having the vacuum flow continuous for clamping or

cycled through the adjustable vacuum level switch for bagging.

The purpose of the cycled or bagging mode is to turn off the

pump once it has reached a preset level, in this case all our

switches are pre set to 25"Hg, and to re-start it when the

vacuum level falls. This cycling mode keeps the bag at full

vacuum but doesn't allow the pump to overheat and activate the

electronic, thermal relay switch that is built into each rotary

vane pump as an extra protection. When using the clamping mode

the pump will automatically bypass the micro switch and reach

its maximum vacuum of between 26 to 27" Hg.

Pro-6

Kit

Mark

6.5 Pump

1/4 Hp

100/115 volt, 50/60 Hz, single phase

6.5 CFM open flow

Clamps at 1700 lbs per sq ft

38 Lbs shipping wt. |

TEMPORARILY DISCONTINUED UNTIL FURTHER

NOTICE

Pro-10

Kit

Mark 10 Pump

3/4 Hp

100/115, 220/240, 50/60 Hz, single phase

10 CFM open flow

57 Lbs shipping wt. |

Included:

*Mark 6.5 Pump (Pictured above)

*54" x 109" - 20 mil Polyurethane Bag

with clamps

(no discount for smaller bags)

*10 feet of vacuum hose

*Illustrated operators manual

*Exclusive "snap-lock" quick hose connector

All for $1,258.80 +Shipping

Pump only: $1,056.25 +Shipping |

Included:

*Mark 10 Pump (Pictured above)

*54" x 109"

20 mil Polyurethane Bag

with clamps

(no discount for smaller bags)

* 10 feet of vacuum hose

* Illustrated operators manual

* Exclusive "snap-lock" quick hose connector

* Can run up to 3 bags at one time, 3

port manifold sold below..

All for $1,674.00

+ Shipping

Pump

only: $1,374.00

+ Shipping

|

| |

|

VHP

Pump (To Right)

The heart of any vacuum

system is the pump and the VHP Pump sets the standard for

every other pump in it’s class on the market today and has

proven to be such an exceptional pump, it is offered as an

upgrade to any existing system. It is the perfect pump for

frame press for

large bag operation and can be manifolded for multiple

bag operations.

Pump only: $2,394.00 +Shipping

|

VHP

Pump

Specifications:

10 cfm, 1/2 hp 110 vac, 3.4 amps

Vacuum level 29.0" Hg

Very high efficiency

Oil cooled, constant operation, rotary vane vacuum pump

60 Hz

Electronic vacuum release solenoid

Dimensions: 16” wide x 14” high x 8” deep

Very High Performance

Shipping wt: 42 lbs

|

|

Note: CFM is a measurement of how fast the pump draws air out of the

bag.

Bag

Upgrade? Simple. Just subtract amount for the bag shown above

in your kit,

then add the price for the bag you

want shown below.

Please

E-MAIL US

if

you have questions about our Vacuum Bagging products. |

|

|

| |

|

REGULATOR: |

Mark

II Electronic Pump Controller

Specifically designed to automatically cycle old

electric vacuum pumps off

and on when they reach a pre-set level of vacuum. The purpose of this

cycling is to prevent the pump from overheating from prolonged use when

vacuum bagging. A front panel, illuminated, three position switch allows

the operator to select either the cycling mode or to bypass the vacuum

level micro control switch when using it in the clamping mode. To

operate you simply plug the pumps power cord and vacuum line into the

back of the controller and everything after that is automatically

controlled from the front panel

Specifications:

100/120

volts, 50/60Hz (220/240 available)

18 gauge, powder coated steel case

Replaceable, fused circuit protection |

Heavy

duty, 20 amp starter relay

16 gauge line cord with grounded plug

Pre-set to 25" Hg, adjustable micro switch |

$422.50

ea |

| |

|

VACUUM

BAGS: |

| We

offer, as standard, in stock products ready to ship vacuum

bags for veneering and forming in three different materials and a

variety of sizes. Each type of material has unique properties that make

them ideally suited for different applications. From the “all

around” versatility and economy of vinyl, the perfect choice for the

small shop and semi-professional to the higher production durability of

polyurethane with its particular conforming properties to the new

“fast evacuation” vinyl bags which are ideal for lamination of flat

stock. In addition, we can make any size bag, to your specifications, in

about five days or less. All of our bags are made with the finest

materials available, to our rigid specifications and are unconditionally

guaranteed against manufacturing defects. |

|

Vinyl

Bag

Specifications and Benefits:

1. Heat welded seams guaranteed not to come apart.

2. Three track, “quick-zip” closure system for easy, fast and

positive bag sealing.

3. Clampless, press fit, air tight vacuum hose connection

electrically welded to the bag eliminating the need to cut a hole in the

bag or to use nuts and washers to seal-off the access hole.

4. Low, economical cost.

5. Completely transparent, water clear film.

6. Easy to repair tears or punctures.

7. 280 lb. tear strength resistance.

8. 2x to 3x elongation or “stretch-ability”.

9. .020 Thickness

|

Electronically

welded through-valve.

Unique

three track “quick-zip” vinyl bag closure system.

|

Comments:

These vinyl bags have been manufactured and sold to

hundreds of

satisfied customers since 1997. They have also been used as pool liners

and as water bed mattresses for decades with excellent results. There

has been the concern that vinyl is not as strong, or puncture resistant,

as polyurethane and to a large extent that is true. However, the

comparison would be better made if you said that polyurethane was like

steel and vinyl was like aluminum, both very strong materials and able

to withstand almost any usage. With proper care, vinyl bags will have a

useful life every bit as long as any other material; plus the cost of

vinyl bags is so low that many users will elect to have bags in two or

three sizes, often at slightly less cost than a single polyurethane bag.

This is the perfect small shop bag. |

|

|

CLOSING THE BAG

The Triple Track E-Z zip Vinyl bag eliminates those difficult to

use bars and clamps to seal the bag. Our “triple track” closure

system makes sealing the bag a snap!

Our poly bags use a

C-Clamp to seal each side, clamps are included.

|

|

|

| |

|

Polyurethane

Bag

Specifications and Benefits:

1.

Seamless construction, guaranteed not to

come apart.

2. “C” clamp closure system, open both ends for

easy handling - 2 “C” clamps supplied with

each bag.

3. Electrically welded, clampless, press fit, air

tight vacuum hose connection.

4. 400 lb. tear strength resistance.

5. 4x to 6x elongation or “stretchability”.

6. .020" or

.030" Thickness

|

“C”

clamp closure system, standard with all poly bags.

|

|

Comments:

Polyurethane is unquestionably stronger and more durable than

vinyl making it the perfect product for a hard working,

production environment. Its “stretchability” also makes it

ideal for highly curved or arched work. It also stays more

flexible over a greater temperature range so you don’t have to

worry about the bag being too stiff to work with in a cool shop.

Polyurethane also has a significantly greater puncture and tear

resistance than vinyl which is also beneficial in a busy

production area. All things being equal, both type of bags will

last a very long time if proper care is exercised but for a high

production application polyurethane is definitely the material

of choice.

|

|

|

We can

make any size bag to your specifications.

If you don’t see what you need here please contact us for a

quote.

Please

E-MAIL US

if

you have questions about our Vacuum Bagging products.

Vacuum Bag Maximum Temperature is 180°

VACUUM BAG PRICING:

*NOW

- 30mil BAGS, When

Strength Matters!!!

|

VACUUM

BAGS

(ALL

SIZES IN INCHES) |

VINYL

20 mil

(zip-lock) |

POLYURETHANE

20 mil

(C-Bar Clamps

Inc.) |

POLYURETHANE

30 mil

(C-Bar Clamps

Inc.) |

| 24 X 36 |

#B2436V - $86.00ea |

not

available |

not

available |

| 36 X 54 |

#B3654V - $114.80ea |

not

available |

not

available |

| 54 X 60 |

#B5460V

- $152.60ea |

#B5460P2 - $230.70ea |

#B5460P3 -

$310.43ea |

|

54 X 85 |

#B5485V - $174.80ea |

#B5485P2 - $262.20ea |

#B5485P3 - $376.55ea |

| 54 X 109 |

#B54109V

- $197.90ea |

#B54109P2 - $313.91ea |

#B54109P3 - $453.98ea |

| 54 X 154 |

#B54154V -

$255.50ea |

#B54154P2 - $404.39ea |

#B54154P3 - $570.27ea |

|

13 X

98 |

#B1398V -

$128.00ea |

#B1398P2 -

$196.20ea |

#B1398P3 - $299.70ea |

|

13 X

194 |

#B13194V

- $163.4ea |

#B13194P2 - $215.10ea |

#B13194P3 - $306.95ea |

|

13 X

250 |

#B13250V

- $191.00ea |

#B13250P2 - $291.00ea |

#B13250P3 - $339.14ea |

|

27 X

98 |

#B2798V

- $164.00ea |

#B2798P2 - $235.80ea |

#B2798P3 - $297.38ea |

|

27 X 194 |

#B27194V -

$251.40ea |

#B27194P2 - $261.30ea |

#B27194P3 - $368.14ea |

| 27

X 250 |

#B27250V -

$297.00ea |

#B27250P2 -

$346.68ea |

#B27250P3 - $426.43ea |

|

ACCESSORIES

BF4X50

BREATHER FABRIC, FELTED POLYESTER, 4' X

50' ROLL

66.75

CB-2 “C” BAR CLAMP FOR VACUUM BAGS, 56”

LONG, EACH 39.50

M c-1 3 PORT MANIFOLD,

ANODIZED ALUMINUM, ¼” NPT

184.40

COMPLETE W/BALL VALVES AND 3/8” HOSE CONNECTORS

VAC HOSE 3/8” OD POLY VAC

HOSE

10’

36.00

25’ 55.50

50’

82.00

100’

118.00

***1/4" O.D. is also available at the

same cost.

|

|

GLUE FOR VACUUM BAGGING:

RECOMMENDED GLUE:

veneer bond

dry resin (DARK OR PURE

WHITE)

14oz. tub

$14.35 / TUB

5 lb. tub $34.95

/ TUB

25 lb. pail $97.20

/ Pail

veneer bond high performance pva

16 oz.

$16.25 / EA

1 qt

$19.45 / EA

1 gal, capped

$36.60 / EA

5 gal, TUB

$128.60 / EA

PRO-GLUE “HIGH

PERFORMANCE” PVA is an

unconventional poly vinyl acetate that is similar to the typical yellow

and white “carpenters” glue except that it has 67% solids compared to the

typical glues whose solid content is 54-56%. This means that it is

“stickier” creating a stronger bond since more of it stays in the joint

where it is needed and it dries harder loosing much of the typical pva

“creep” that is associated with the less solid brands.

veneer bond

veneer softener

1 qt with trigger sprayer

$27.90 / EA

16 oz w/trigger sprayer

$19.85 / EA

1

gallon

$42.75 / GALLON

CLICK FOR GLUE SPECS

CLICK FOR GLUE

TIPS

CLICK FOR GLUE

TIPS

|

Other Recommended Products for Vacuum Clamping:

Epoxy Resin

Hardener

Thickener, Talcum or Baby Powder

1/8" x 1/16" Disposable Plastic Trowels.

Clear Plastic Food Wrap

Box Tape

Plastic Cups and Bowls

(*Titebond2 is also used by some of our

customers, some instructions below can be ignored when using Titebond2)

Mixing Instructions:

Follow MFG Instructions and/or:

1. Have plastic containers ready for mixing.

2. The hardener is mixed in at 1:5

3. Mix until a uniform color is achieved.

4. Add thickener to thicken almost to a "mayonnaise"

consistency.

Vacuum Clamping:

Follow Instructions included with your machine and/or:

1. Spread out glue with trowel on your substrate, not veneer.

2. Place veneer in position on substrate. Use box tape to hold in place.

Tip: Try not to get glue resin on veneer face, will show up on when

finishing.

3. Use clear plastic food wrap to cover up edges where glue will squeeze

out.

4. Place project in Vacuum Bag on top of your clamping board or form.

5. Seal Vacuum Bag and turn on the Vacuum unit.

6. You should leave your project in the bag for at least 3-1/2 hrs.

Tip: Clamp time may differ with climates, longer for wood forming. See

Glue MFG

specs.

Clamping Boards & Forms:

A clamping board is put in your bag before clamping. Operators usually

have a few different sized boards for their projects. The board is usually

at least 4" larger than the project on all sides. A 3/4" 2-sided melamine

board is what we recommend for the clamping board because it allows you to

easily slide in and out your project. Shallow cuts must be made into this

clamping board on the front and back, about 1/32" deep is fine and the

hose must protrude through the bag into a hole in the edge of the clamping

board that in turn, is ported into the cuts you have made. Lastly,

round-over and sand the outer edges of the board and sand the shallow cuts

you have made.

Forms are used for making custom curved plywood pieces or other items.

These are done may different ways and made of wood. You must build your

form very strong to withstand the 1700lbs per sq. ft. that the unit will

supply. For custom forming, we recommend the Pro 5 kit as the smallest kit

to be used.

Closing:

Vacuum Clamping is a procedure that has many different techniques. Many

users have their own tricks they have perfected. Experimenting with your

system can be fun and educational for individual users and profitable for

your business.

Always

follow manufacturer recommendations also for mixing, storage and

safety warnings.

Titebond2 is a trademark of Titebond2. |

|

Go To Products Page

| |

************

|